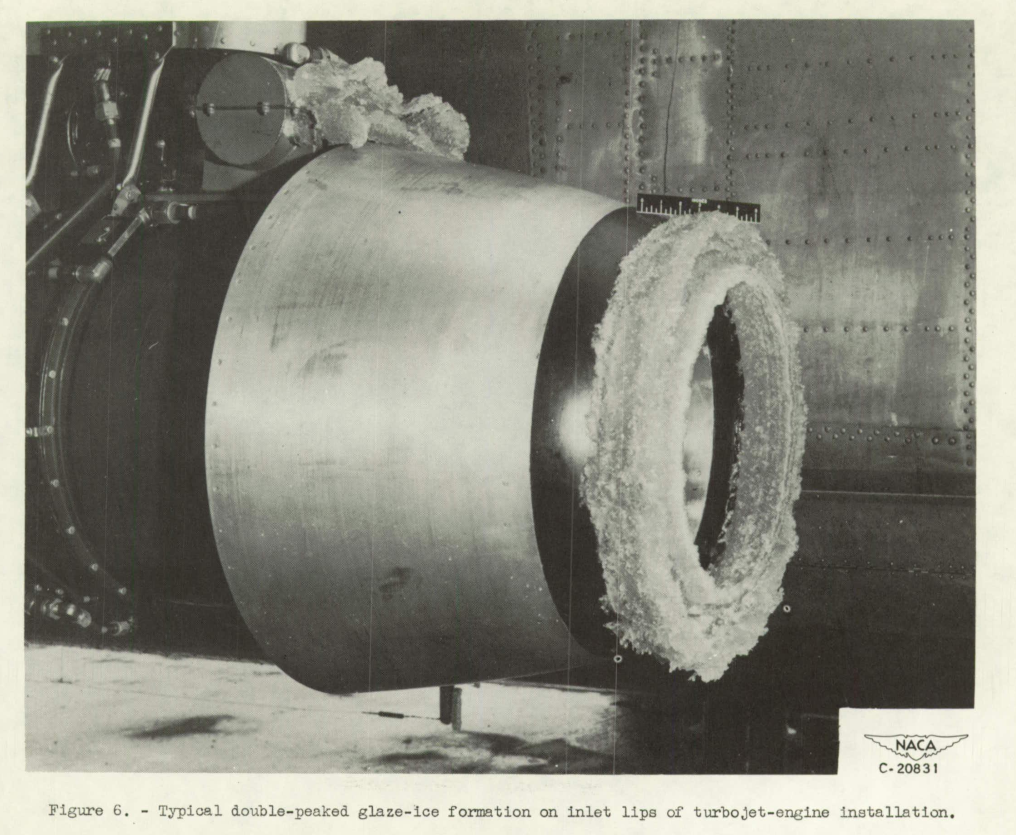

"Aircraft are now capable of flying in icing clouds without difficulty, however, because research by the NACA and others has provided the engineering basis for icing protection systems"

"THE ICING PROBLEM - CURRENT STATUS NACA TECHNIQUES AND RESEARCH" 1

Abstract

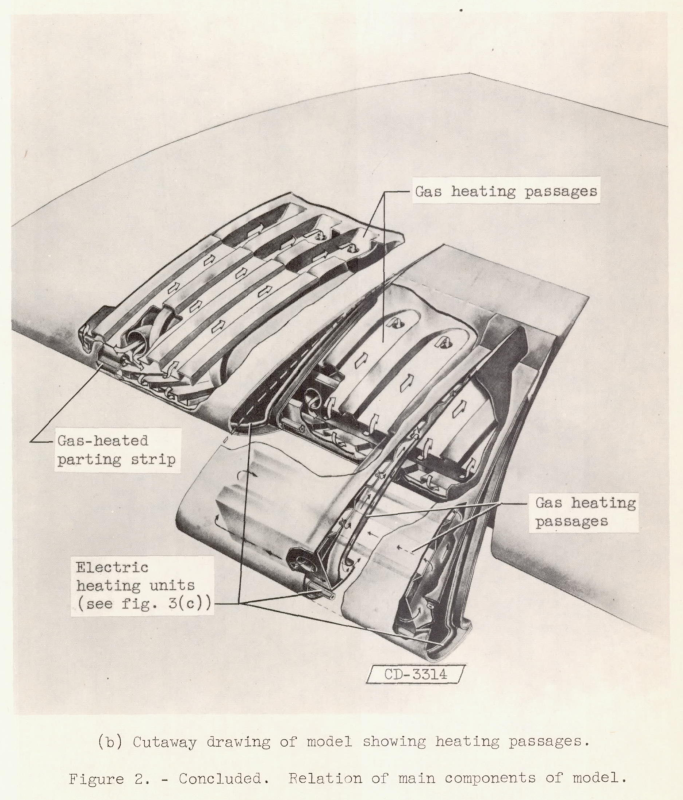

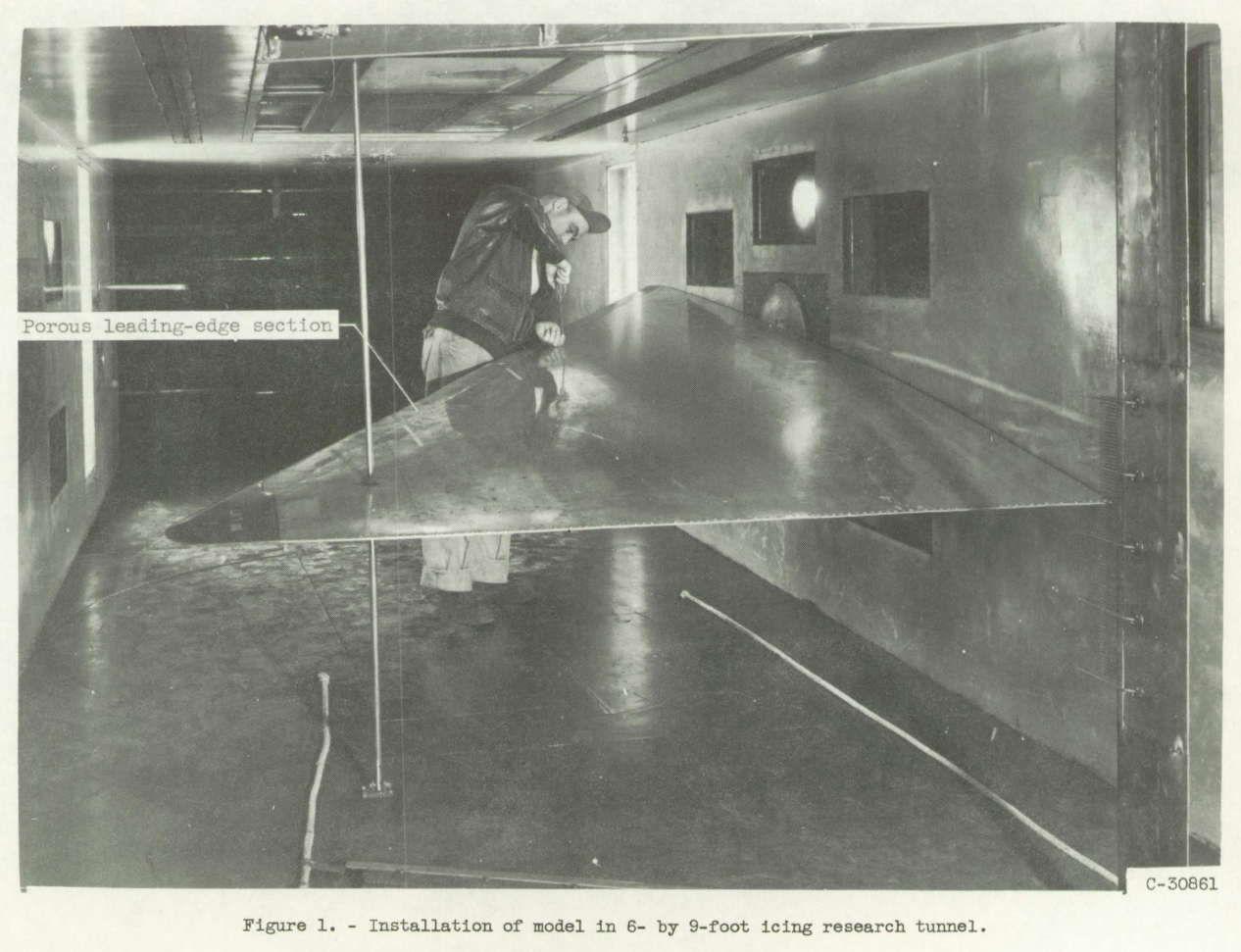

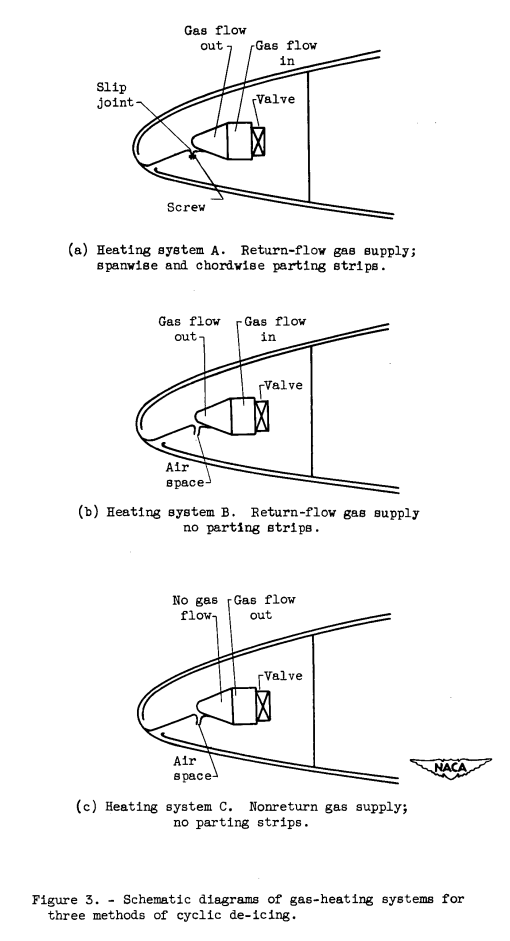

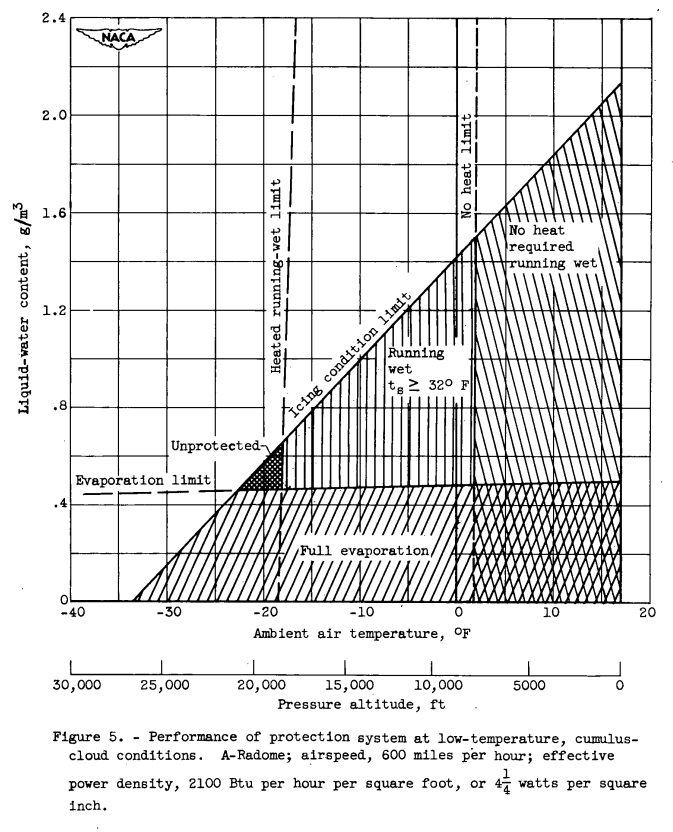

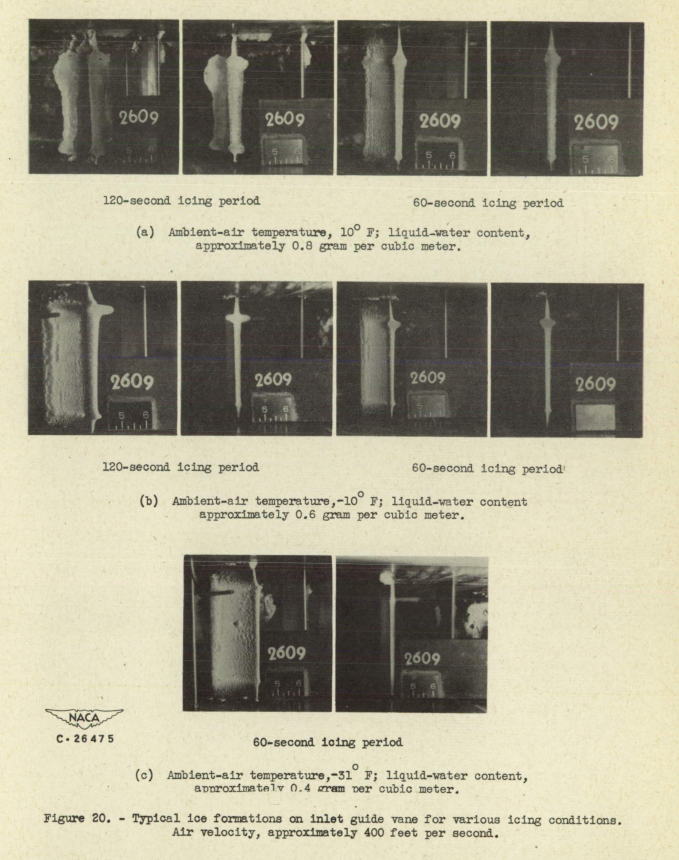

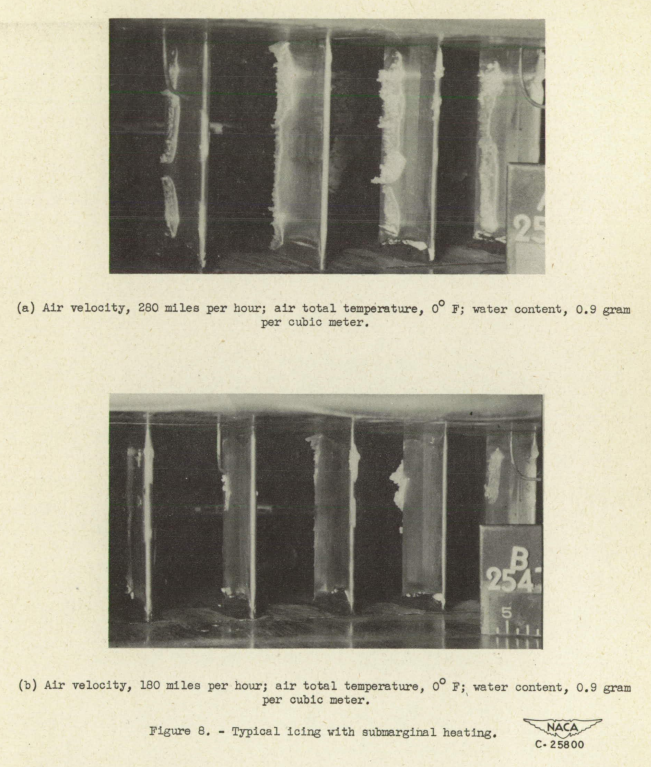

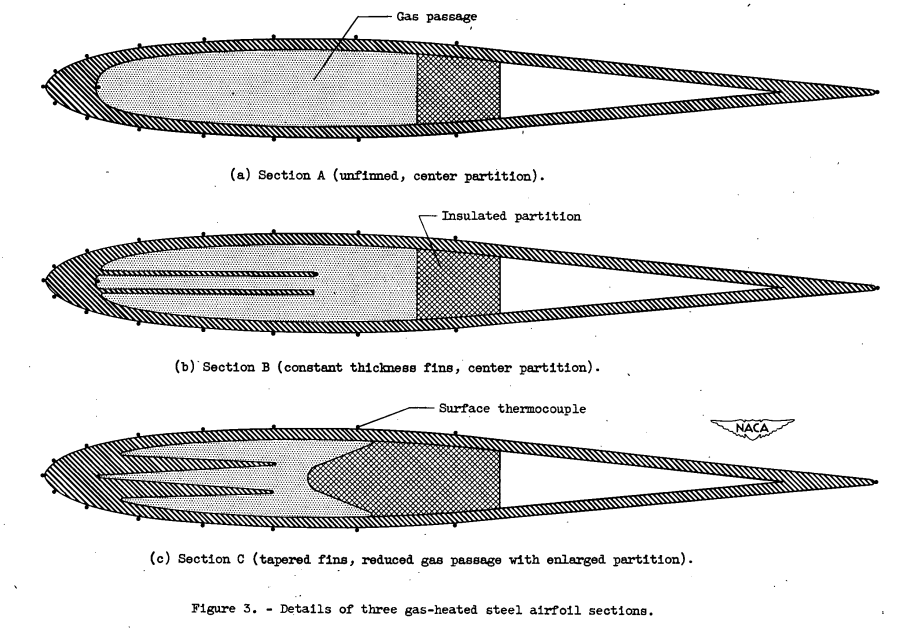

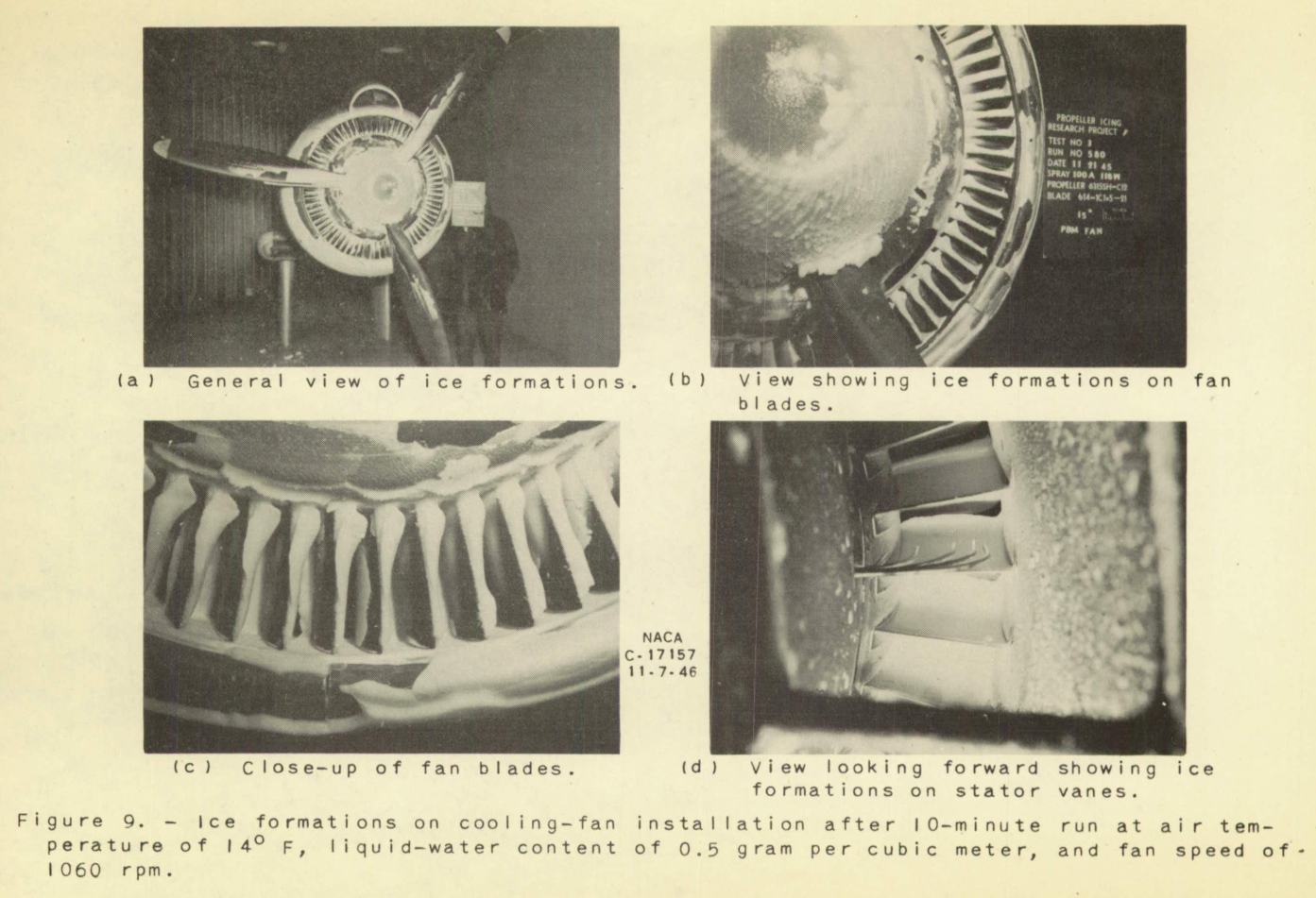

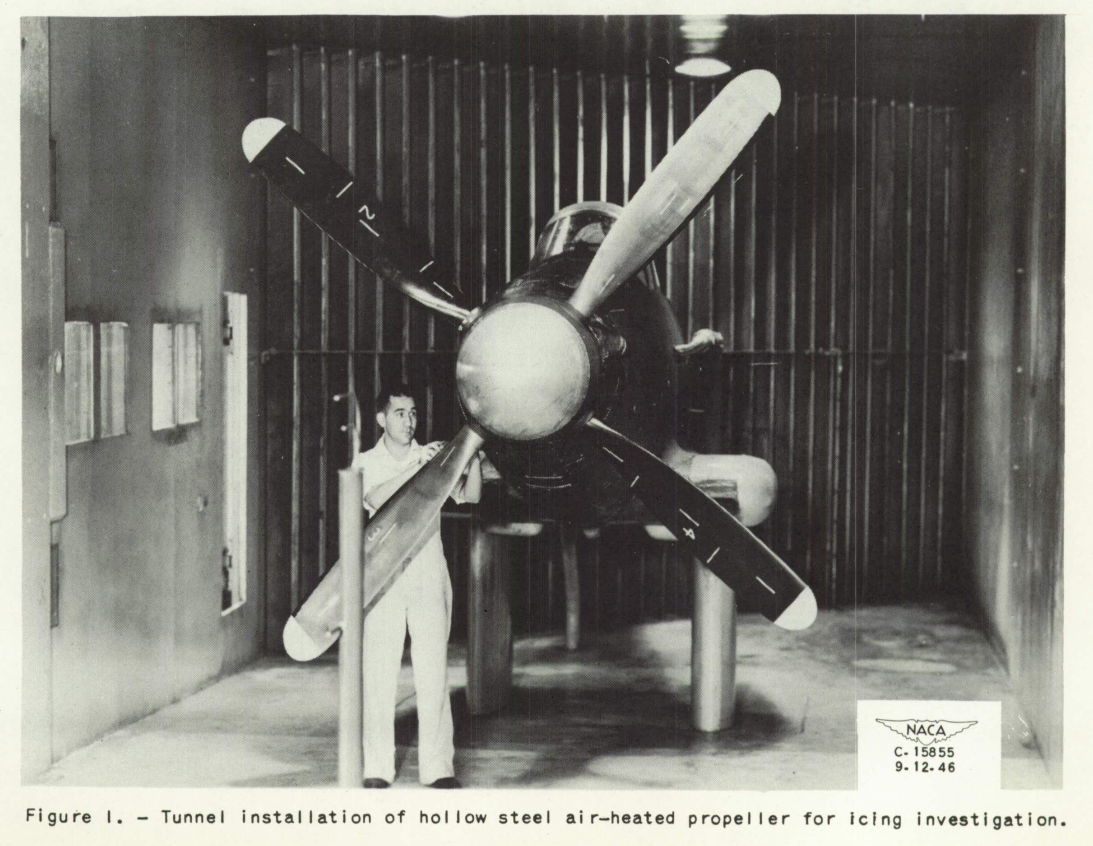

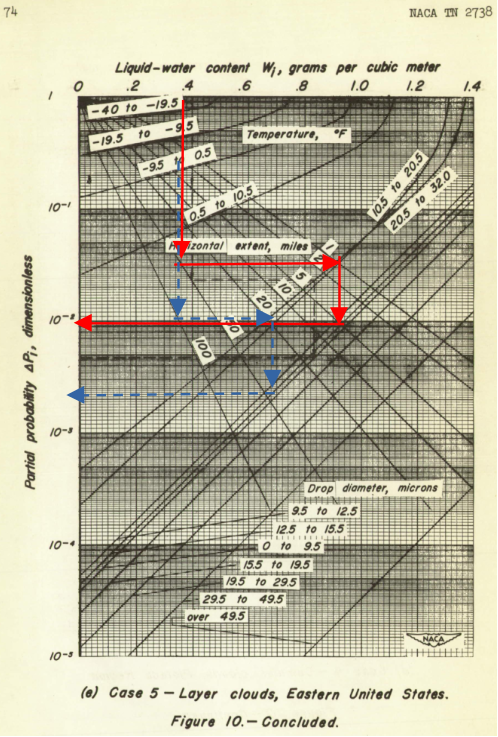

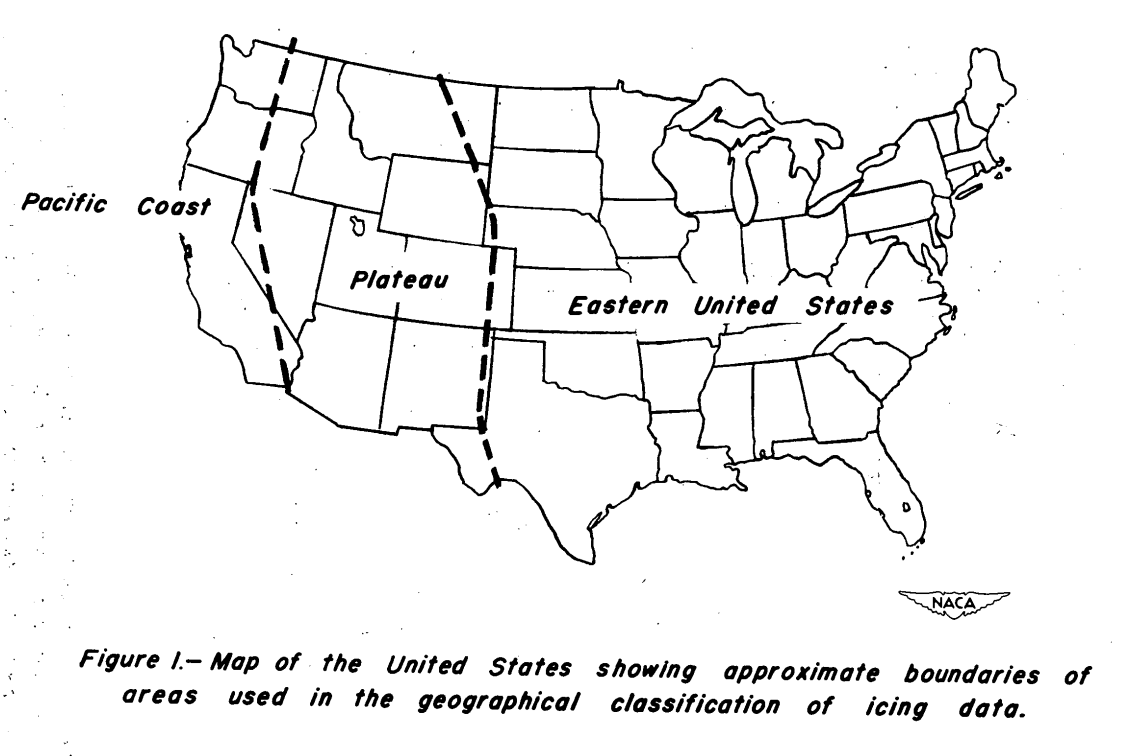

This paper summarizes some of the techniques used in N.A.C.A. research programs, in flight and in tunnels, to solve aircraft icing problems and it indicates the scope of the data available for the design of aircraft icing protection systems. Sufficient data have been obtained, generalized where possible, and techniques have been established whereby icing-protection requirements for most aircraft components can be determined sufficiently accurately for engineering purposes. The Appendices discuss the icing facilities at the N.A.C.A. Lewis laboratory in detail, specific test equipment and techniques used in conducting tests in icing wind tunnels, and several icing instruments.

Introduction

This is an excellent summary by Uwe …

read more

From

From