"Tests to determine the performance of an icing protection system ... are of little value ... unless they can be subjected to an analytical treatment, and reduced to a generalised form which is applicable to conditions other than those under which the tests were actually made."

Lecture No. 12b, "NOTE ON THE FLIGHT TESTING AND ASSESSMENT OF ICING PROTECTION SYSTEMS" 1

Summary

An alternative view of how to correlate icing conditions to ice protection performance.

Key Points

- The concepts of protection system "failure" vs. "deficiency" are discussed.

- Test conditions specifically planned to find the point of failure or deficiency are recommended.

Abstract

Flight tests of an icing protection system consist of functioning tests, tests to determine the internal efficiencies, and tests of the performance in icing. The performance in icing can be determined only if the appropriate measurements are made, and if the flow of protection or the icing severity can be adjusted. The results can be reduced to standard conditions, using theoretical corrections, and can be plotted on a diagram to show whether performance meets design requirements, or to assess the degree of protection afforded by the ultimate, or any lower, performance.

Discussion

This publication addresses several modes of ice protection. For brevity, I will discuss the sections about fluid protection systems only. There are interesting comments on thermal anti-ice and deicing that the reader may wish to find in the full publication.

There are no figures or citations included with Lecture 12b. This was true for two different printed copies of the Airplane Icing Information Course that I borrowed. Both copies were in good shape with no obviously missing pages. There is a copy of a similar report with the same title at the NRC library that has the figures 3 (copyrighted, but freely available). However, I am not going to show the figures here.

1.0 INTRODUCTION

Tests to determine the performance of an icing protection system are like those to determine the performance, stability or control of an aircraft, in that they are of little value, or can even be misleading, unless they can be subjected to an analytical treatment, and reduced to a generalised form which is applicable to conditions other than those under which the tests were actually made. Particularly in the case of icing trials, it is quite impractical to cover or obtain the range of conditions necessary for sound empirical data. The purpose of this paper is to indicate (not to demonstrate) a procedure for performing icing trials and reducing the results to give a practical answer. The procedure outlined presumes that sufficient preliminary analysis and tests have been made for the basic characteristics of the protective system to be understood, and to be expressible in a theoretical form. It also presumes an ability to measure cloud properties, and for the purpose of assessing the results, depends on the availability of a representative collection of statistical icing data.

2.2 Performance Tests

Freezing-point depressant systems have to be calibrated mainly in terms of the distribution of the liquid, the efficiency being measured as a distribution factor which will vary with flight conditions. The internal performance tests thus become integral with the functioning tests.

2.2.2 Performance in Icing

The only flight tests which can have any value are those in which a correlation can be established between the severity of the icing conditions and the rate at which icing protection is supplied. This correlation can be established satisfactorily at points where the rate of protection is just sufficient for the ambient icing conditions.

It is first absolutely necessary to have suitable instrumentation to measure air temperature, liquid water content, and, if practicable, droplet-size and distribution, whether the icing is simulated or natural. Due to the rapid variations in many natural icing conditions, these instruments should give at least a semi-continuous reading. Suitable test instrumentation for this purpose, is, in general, available. If a fixed-rate protective system is used, it can only be tested by varying the icing conditions till a deficiency or failure* becomes apparent. This implies the use of simulated icing conditions, with the attendant difficulties of simulation and operation, or else an indefinitely prolonged programme of seeking natural icing conditions of the right degree of severity. Thus, even if it is the intention to use a fixed-rate system in production, it is worth modifying the test installation to give a controllable rate.

*For definitions of "deficiency" and "failure", see author's paper on "Meteorological Design Conditions for Icing Protection Systems" 2.

From "Meteorological Design Conditions for Icing Protection Systems":

[Emphasis added.]

5.0 PERFORMANCE CHARACTERISTICS OF VARIOUS SYSTEMS AND COMPONENTS

Before considering how these requirements should be applied to various protective systems and aircraft components, it is necessary to discuss the performance and failure or deficiency characteristics of each system. In normal engineering parlance, failure is a fairly definite condition, from which there is no recovery. Therefore when using the word in connection with an icing protection system it should signify that the system has ceased to be effective for the remainder of the icing encounter. Owing to the variety of behaviour of various systems, it is necessary to define failure for each system.

However, protection may cease to be effective for a while in severe icing conditions and then recover completely or partially when the icing severity is reduced. In such a case the system could be called "deficient".

The following examples contain mention of the performance, failure, and deficiency characteristics of various systems applied to various components. It will be seen that in all cases, deficiency or failure may be difficult to define, except perhaps through some secondary effect.

5.2 Freezing-point Depressant

When a depressant is used as a pure anti-icing system as in the case of an alcohol spray, the system is found to be about equally sensitive to rate-of-catch and air temperature. This is probably equally true when the system is applied to de-icing, as on wings. Again, this system becomes deficient when ice starts to form, but this ice will be mushy and will blow off easily, so that deficiency can only be defined by a secondary effect such as a given increase of drag on a wing or loss of thrust in an engine. Recovery will occur in reduced conditions by melting or shedding of the ice, but a secondary effect, such as the damage to an engine, may result in virtual failure before recovery.

2.3 Observations of Deficiency and Recovery

It should also be possible to obtain both qualitative and quantitative observations of the effects of a deficiency, by which is meant an inability to perform the anti-icing or de-icing functions completely, and of the ability of the system to recover from a condition of deficiency. This is of considerable importance in the assessment of the protective system, since it enables a decision as to whether short periods of deficiency can be tolerated. Observations can be obtained by reducing the flow of protection below that required in the test conditions.

4.0 ASSESSMENT OF DEGREE OF PROTECTION

Suppose Fig. 2 shows the adjusted performance curves for an aircraft component for the worst conditions of speed and altitude. It wiLl be seen that the maximum flow of protection is sufficient for 1012 of a total of 1018 recorded icing situation, and 75% of the maximum flow would deal with 983. The degree of protection afforded on that component could then be assessed as 99% for maximum flow, and 97% for 75% of maximum flow.

The various other components of the aircraft would be treated in a similar fashion, and thus the lowest degree of protection for the whole aircraft could be obtained.

The results of such an assessment can be used to decide on modifications the protective system, or to set operational limitations on the aircraft, or for fairly direct comparison with other aircraft and other systems of protection.

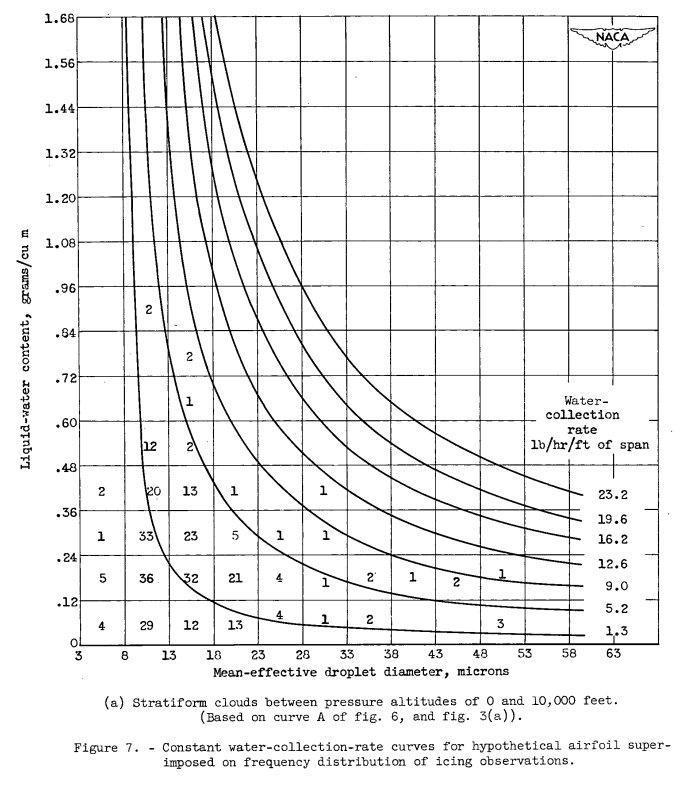

The discussion can be illustrated with figure 7 from NACA-TN-2569. For a fluid ice protection system, the fluid flow rate required is proportional to the water catch rate. "Note on Flight Testing ..." shows that it is only a weak function of ambient temperature and other factors.

If a system can be shown to provide protect at a water catch rate of 12.6 lbm/hr/ft-span, then complete protection is provided for all icing cases in figure. If ice protection fluid flow rate is reduced so that ice begins to form at 9 lbm/hr/ft-span (about 29% less flow), then protection is provided for about 99% of the cases. Further reducing flow so that the performance threshold is 5.2 lbm/hr/ft-span, then protection is provided for about 95% of the cases. A marked reduction in protection flow yields relatively few more cases of complete ice protection.

However, the effects of the cases where complete ice protection need to be assessed to determine if these are acceptable "deficiencies" or unacceptable failures.

5.0 CONCLUSIONS

5.1 Icing protection performance tests cannot be interpreted unless

(a) Measurements are made of the meteorological conditions encountered on the tests

(b) The flow of icing protection can be adjusted to be just adequate for the conditions encountered, or, conversely, icing conditions can be adjusted, by simulation, to suit the rate of protection

(c) The flow of icing protection can be measured

(d) The performance characteristics or the protective system are understood and known.5.2 If these conditions are met, it should be possible to extrapolate from the results of a few icing encounters to obtain the ultimate performance of the system.

5.3 It should also be possible to obtain a quantitative assessment of the degree of protection afforded by the ultimate, or any lower, performance of a system.

5.4 Hence, it should be possible to obtain a true and complete picture of the effectiveness of an icing protection system without the expenditure of excessive time and effort in the search for extremely severe icing conditions.

5.5 Such results cannot be obtained, however, unless sufficient emphasis has been place on research into the basic theories of icing and of protective systems, supported by tests to determine the fundamental performance parameters. However, sufficient knowledge has been obtained at the moment to enable icing protection performance tests to be made on a fairly sound basis.

There are some parallels between this publication and NACA-TN-2569 (NACA-TN-2569 is referenced by Fraser in 2, but no citations at all are included in "Note on Flight Testing..."). This publication focused on flight tests of protection systems, while NACA-TN-2569 focused on design criteria. However, both had a realization that it was not practical to design protection systems for every conceivable condition.

NACA-TN-2569 states the motivation for allowing some tolerance to ice protection performance:

the heat required for protection for this [severest] situation is several times that required for the most probable icing condition.

"Note on Flight Testing..." has the concept of performance deficiency, described above. NACA-TN-2569 describes a similar concept:

The method also illustrates the desirability of exploiting the tolerance of various components to small quantities of ice accumulations, because the frequency of encounter of icing situations with extremely high ice-collection rates is low.

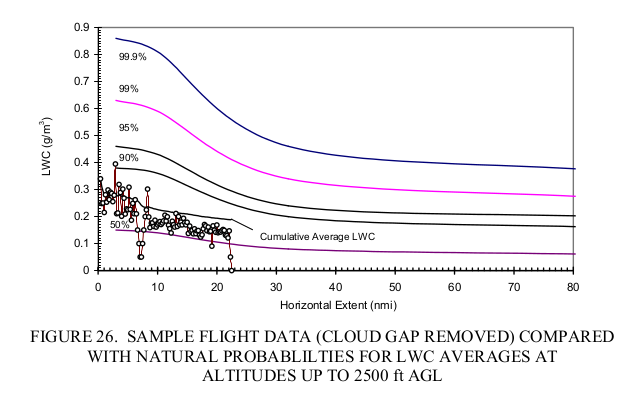

Later, Jeck 4 made plots of the probability of exceeding liquid water content levels (Jeck did not reference Fraser):

I plan to eventually review Jeck 4 in more detail. (Jeck's works merit an entire thread devoted to them.)

Notes

-

Fraser, Don: Note on the Flight Testing and Assessment of Icing Protection Systems. Low Temperature Laboratory, NAE, Ottawa, Canada, Lecture No. 12b, University of Michigan Airplane Icing Information Course, 1953. (8 pages) ↩

-

Fraser, Don: Meteorological Design Requirements for Icing Protection Systems. Low Temperature Laboratory, NAE, Ottawa, Canada, Lecture No. 12a, University of Michigan Airplane Icing Information Course, 1953. (36 pages) ↩↩

-

Fraser, Don: Note on the flight testing and assessment of icing protection systems. LR-50, 1953. (11 pages)nrc-publications.canada.ca ↩

-

Jeck, Richard K., Icing Design Envelopes (14 CFR Parts 25 and 29, Appendix C) Converted to a Distance-Based Format, DOT/FAA/AR-00/30, April, 2002. tc.faa.gov ↩↩