"Considerable time [was devoted] to means for controlling the amount of water sprayed into the air stream, the size of water particles, and the temperatures of the air and water" 1

Summary

Calibration methods evolved during the NACA-era

Key Points

- Early tests had informal calibrations, partly due to a limited understanding of the natural icing environment.

- Rotating multicylinders were the most used means of calibration.

- Water spray nozzles were improved circa 1949.

- The understanding of the natural icing environment had also advanced by 1949.

Discussion

As implied from the quote above from the year 1929, the calibration of an icing wind tunnel is often not just measuring what the facility produces, but also altering and improving the facility to achieve target values for water drop size and liquid water content, and producing a water drop spray that is uniform "enough".

Early calibrations

Two early icing wind tunnel tests had informal calibrations (compared to today's standards 2).

NACA-TN-339, 1930 (Langley Refrigerated Wind Tunnel) 3:

Certain preliminary tests were made in the wind tunnel to determine the best form of water spray necessary to produce ice of smooth appearance and which would be similar in structure and form to that observed in flight (Reference 12), in order to make a study of possible preventives. It was found that the character of the formations obtained depended to a great degree on the quantity of water admitted to the tunnel per unit of time. A spray which consisted of large drops was found to use excessive quantities of water which could not be properly regulated without giving very poor dispersion in the jet, and which gave formations of ice on the model of a very different shape from any obtained in flight. A spray, which consisted of very small drops, was found to be quite satisfactory and was used in all the following tests, as it could be easily controlled to give even dispersion across the air stream at any desired rate of water output.

NACA-TN-712, 1939 (Langley 7-foot by 10-foot wind tunnel) 4:

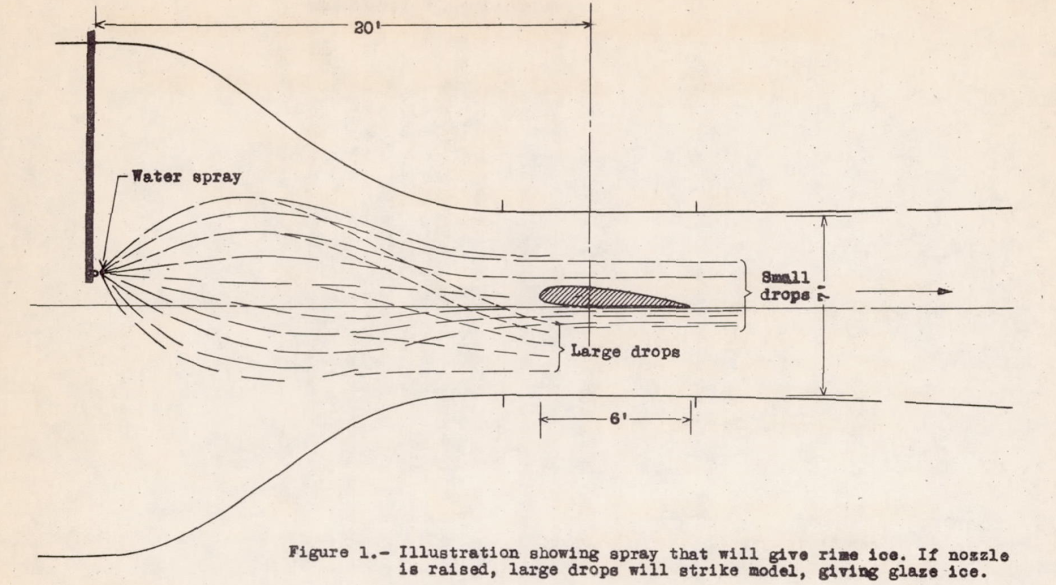

Natural precipitations were simulated by admitting water to the air stream through a spray nozzle. The tunnel test section with the model and the spray are diagrammatically shown in figure 1.

[There will be a discussion of this figure when we get to "Large Drop Icing" in the Icing Wind Tunnel Test thread]

The range of control over the formation of ice was such that a simulation of all typical ice formations found in flight could be produced.

Calibrations in the IRT

Calibrations methods in the NACA Lewis Icing Research Tunnel (IRT) evolved over time.

Drop size calibration methods:

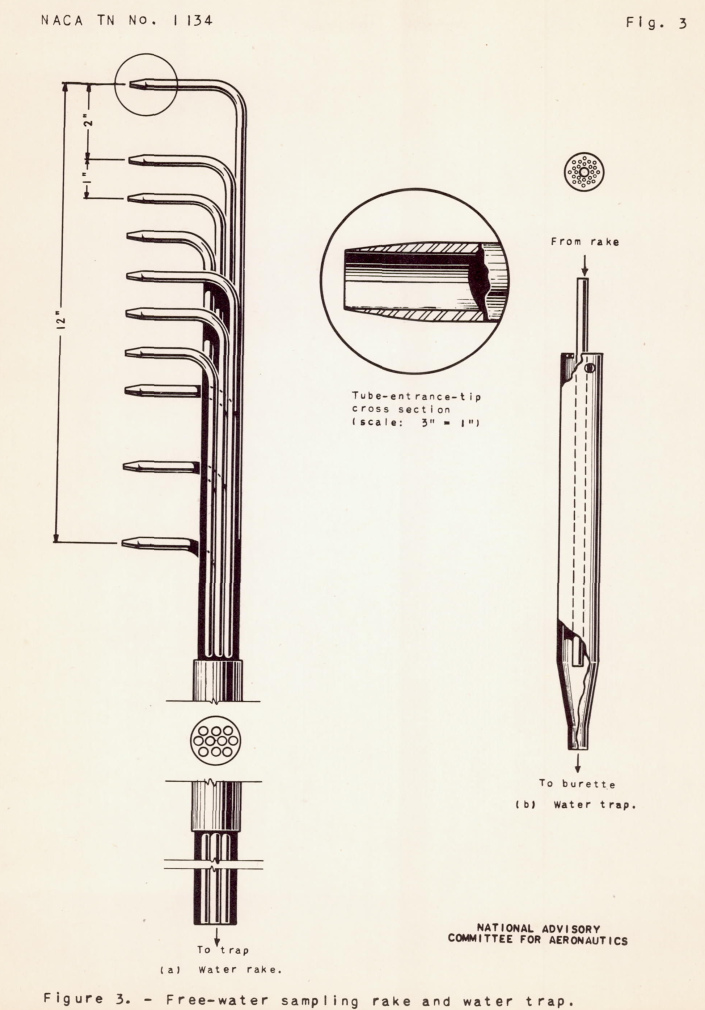

1946 NACA-TN-1134 pool of castor oil

1947 NACA-TN-1246 rotating multicylinders

1948 NACA-RM-E8A27 rotating multicylinder "by volume maximum"

(new nozzles design circa 1949, per "We Freeze to Please")

1950 NACA-RM-E50I08 rotating multicylinder MVD

1951 NACA-RM-E51B12 "in the range of natural icing conditions"

1951 NACA-TN-2480 (apparently multicylinder) "the mean-effective droplet diameter was varied from about 8 to 12 microns by adjusting the nozzle-air pressure" *

1952 NACA-TN-2615 absorbent cylinders (special purpose in transonic tunnel)

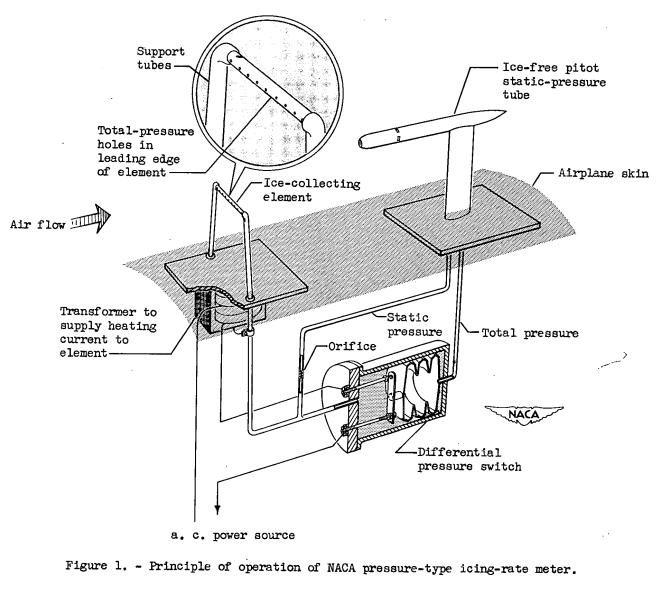

1953 NACA-TN-2962 "The icing conditions were determined from a previous calibration of the tunnel and periodically checked with a pressure-type icing-rate meter"

1955 NACA-RM-E54I03 "the results shown were calculated from unpublished wind-tunnel water-droplet impingement data obtained by means of water droplets carrying dye in solution."

* I note this because it implies that they had enough confidence in the control systems and prior calibrations so that conditions could be set just by the spray control parameters.

LWC calibration methods:

1946 NACA-TN-1134 free-water sampling rake

1947 NACA-TN-1246 rotating multicylinders

1948 NACA-TN-1586 rotating cylinder grid

1952 NACA-TN-2615 absorbent cylinders (special purpose in transonic tunnel)

1953 NACA-TN-2962 "The icing conditions were determined from a previous calibration of the tunnel and periodically checked with a pressure-type icing-rate meter"

1955 NACA-TN-3338NACA-TN-3338 cylinders, ribbon, aspirator

1955 NACA-TN-3564 "Liquid-water content was measured by means of a pressure-type icing-rate meter"

1956 NACA-TN-3839 Joukowski-aspirator

1957 NACA-TN-4155 "Liquid-water content was measured by means of a pressure-type icing-rate meter"

1958 NACA-TN-4268 "The cloud total liquid-water content was obtained by collecting dye from the spray cloud in an aspirating device (a tube that draws in the cloud at free-stream conditions)"

Selected images

from NACA-TN-1134

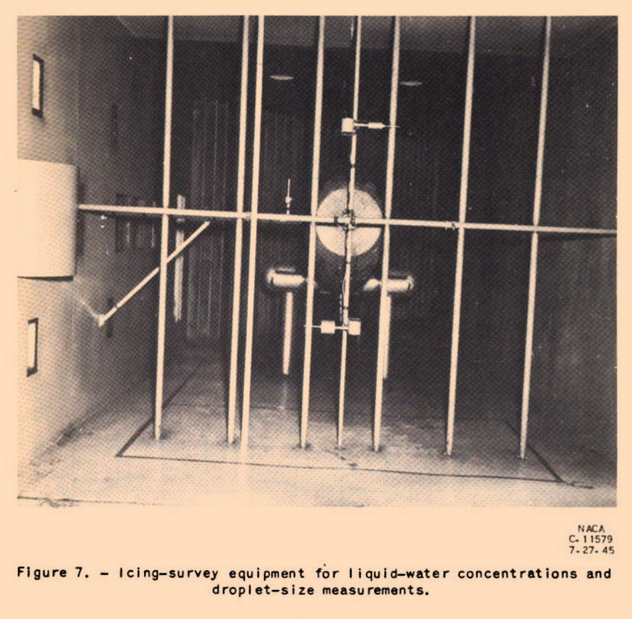

from NACA-TN-1520

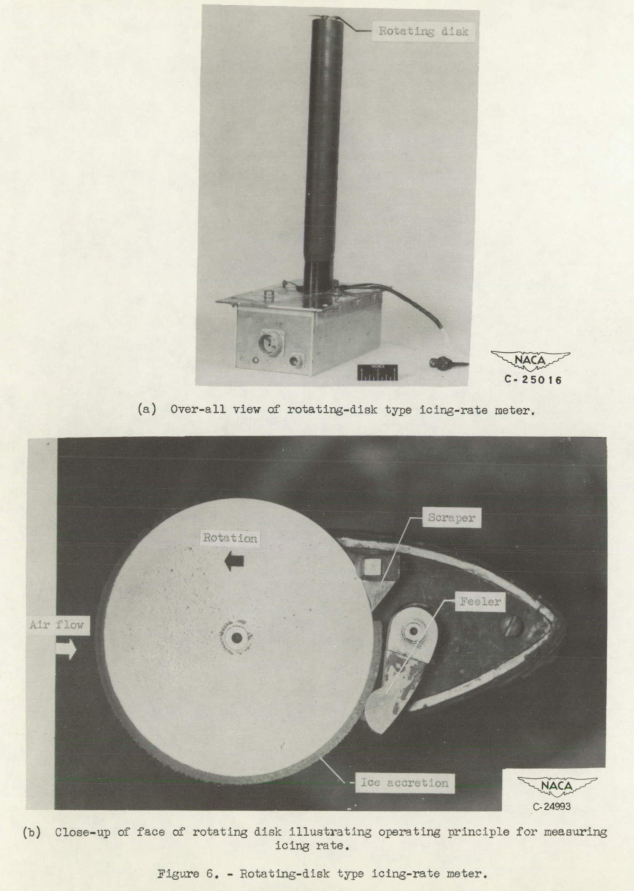

from NACA-RM-E51E16

from NACA-RM-E51E16

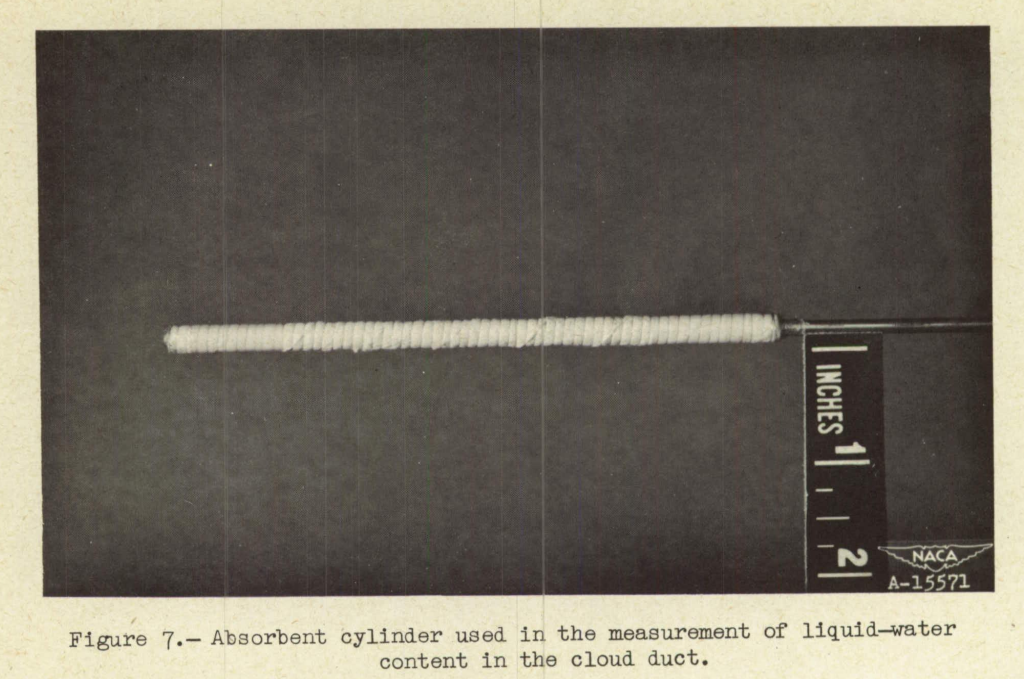

from NACA-TN-2615

from NACA-TN-3839

NACA water spray calibrations

(In approximate chronological order)

Note that while NACA-RM-E50K10 was published in 1951,

it contains data from a test conducted in 1945.

| Publication | LWC calibration | MVD calibration |

|---|---|---|

| NACA-RM-E50K10a | not stated | not stated, 35 micrometer "based on volume maximum" |

| NACA-TN-1134 | free-water sampling rake | Castor oil pool |

| NACA-TN-1246 | multicylinder | multicylinder 55 MVD |

| NACA-TN-1520 | rotating cylinder grid | multicylinder 55 MVD |

| NACA-TN-1691 | rotating cylinder grid | multicylinder 55 MVD |

| NACA-TN-1586 NACA-TN-1587 NACA-TN-1588 | rotating cylinder grid | multicylinder 55 MVD |

| NACA-RM-E8A27 NACA-RM-E8A28 NACA-RM-E8A29 | multicylinder | multicylinder 12 to 15 micrometer "by volume maximum" |

| NACA-RM-E9EO6 | multicylinder | multicylinder "in the range of natural icing conditions" |

| NACA-RM-E9E12 | not stated | not stated |

| NACA-TN-1789 | multicylinder | multicylinder 15 to 20 micrometer "by volume maximum" |

| NACA-RM-E50I08 | multicylinder | multicylinder 10 to 15 MVD |

| NACA-RM-E50E03 | multicylinder | multicylinder 10 MVD |

| NACA-RM-E50H29 | "measured" | "measured" 15 MVD |

| NACA-TN-2480 | rotating cylinder | (apparently multicylinder) "the mean-effective droplet diameter was varied from about 8 to 12 microns by adjusting the nozzle-air pressure" |

| NACA-RM-E51E16 | not stated | not stated |

| NACA-RM-E51B12 | multicylinder | multicylinder "in the range of natural icing conditions" |

| NACA-RM-E51J29 | not stated | not stated |

| NACA-RM-E51J30 | multicylinder | multicylinder 6 to 10 MVD |

| NACA-RM-E53C27 | not stated | not stated 8 to 18 MVD |

| NACA-TN-2962 | "The icing conditions were determined from a previous calibration of the tunnel and periodically checked with a pressure-type icing-rate meter" | dye-tracer technique 10 to 16 MVD |

| NACA-RM-E53E07 | not stated | not stated |

| NACA-RM-E52J31 | not stated | not stated |

| NACA-RM-E53C26 | not stated | not stated |

| NACA-RM-E53J30 | not stated | not stated |

| NACA-RM-E54I03 | pressure-type icing-rate meter | "the results shown were calculated from unpublished wind-tunnel water-droplet impingement data obtained by means of water droplets carrying dye in solution." |

| NACA-TN-3338 | cylinders, ribbon, aspirator | cylinders |

| NACA-TN-3564 | "Liquid-water content was measured by means of a pressure-type icing-rate meter" | "Icing - cloud droplet size was obtained from a previous calibration obtained by using water droplets carrying dye in solution" |

| NACA-TN-3839 | Joukowski-aspirator | multicylinder |

| NACA-RM-E56B23 | not stated | not stated |

| NACA-RM-E56E11 | not stated | not stated |

| NACA-TN-4155 | "Liquid-water content was measured by means of a pressure-type icing-rate meter" | "Icing-cloud-droplet size as a function of spray-nozzle pressure settings was determined from a previous calibration of droplet size obtained with water droplets carrying dye in solution" |

| NACA-RM-E57G09 | not stated | not stated |

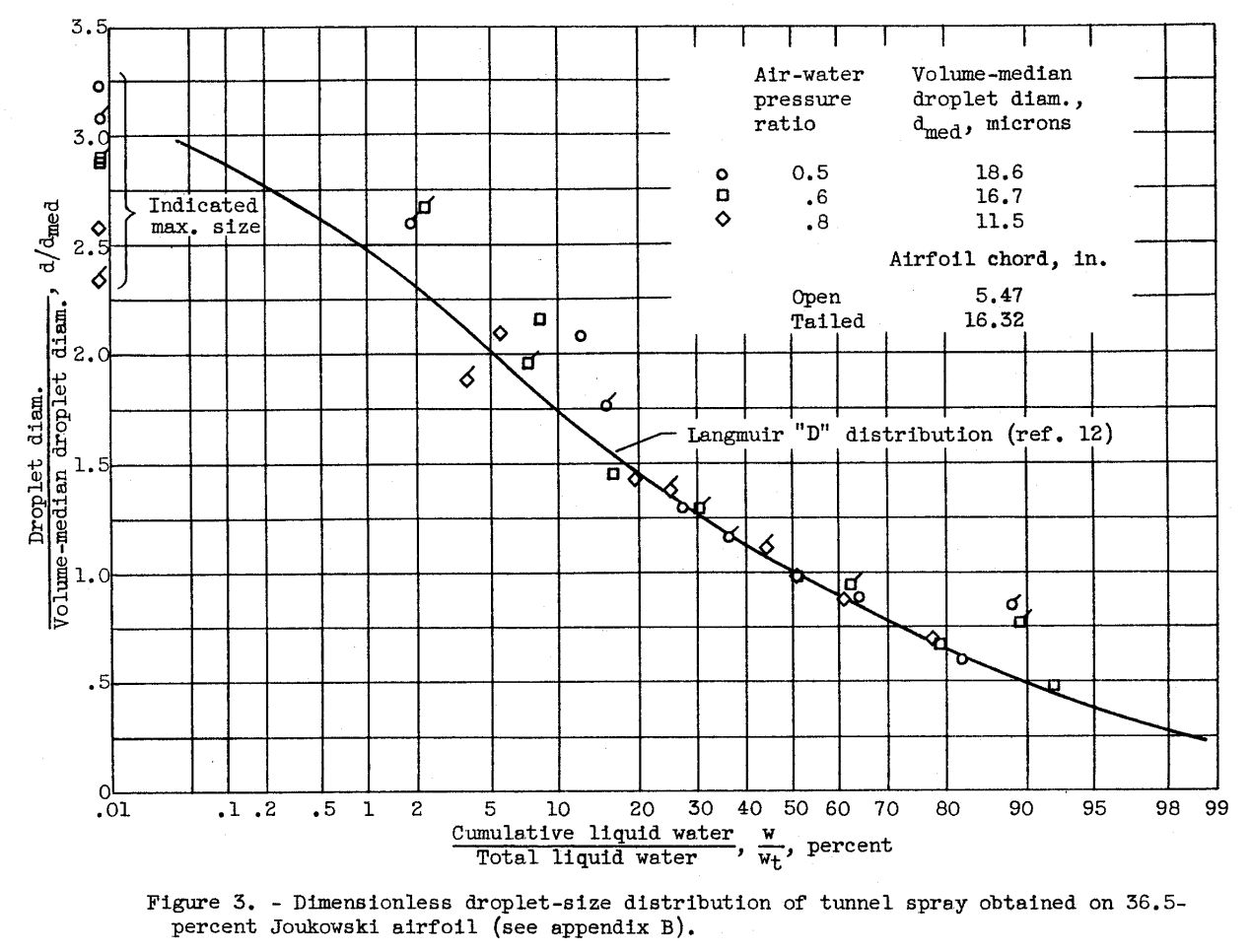

| NACA-TN-4268 | "The cloud total liquid-water content was obtained by collecting dye from the spray cloud in an aspirating device (a tube that draws in the cloud at free-stream conditions)" | "The cloud droplet size and size distribution were determined by experimental and theoretical impingement on a 36.5-percent-thick symmetrical Joukowski airfoil" |

Natural icing conditions characterizations

Calibration may be thought of as understanding the conditions that a facility can achieve.

Another step is knowing what the flight conditions are that one wants to simulate.

The understanding of natural icing conditions was also evolving in the NACA-era. This topic merits a thread of its own, but for now I will very briefly summarize.

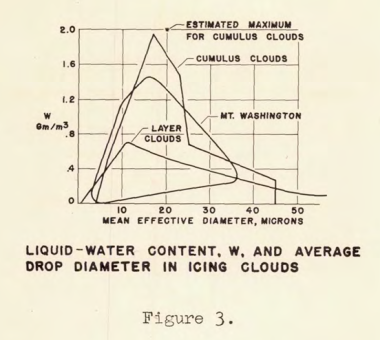

In 1947 there was some understanding of MVD and LWC targets. This figure is from a presentation by William Lewis 5.

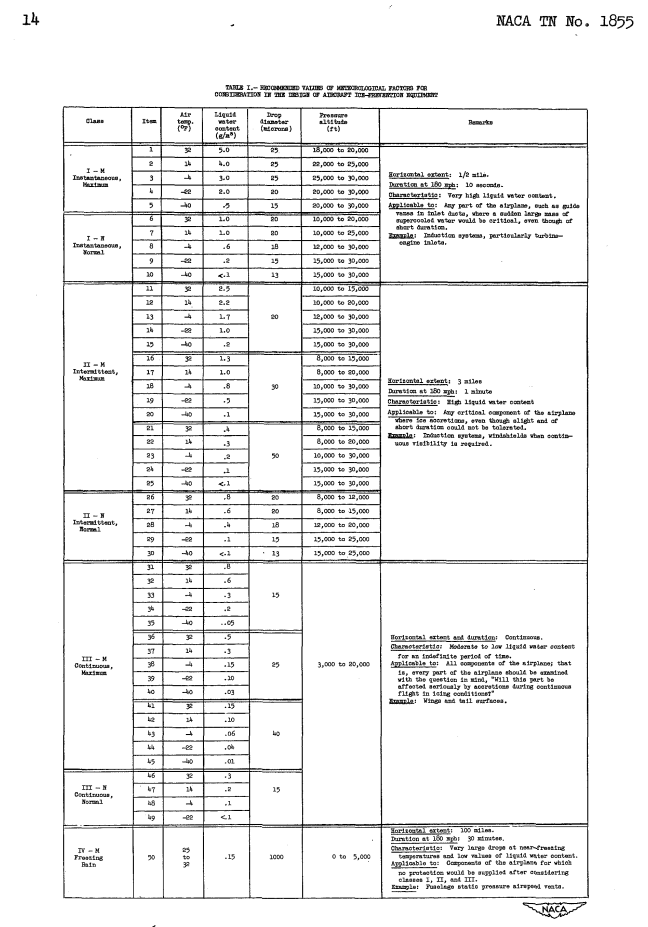

This had advanced by 1949 to something close to our current understanding. As mentioned in the Conclusions of the Cylinder Thread, the current icing regulations environment definition was largely determined by a few NACA publications, NACA-TN-1855 6 being one of them. Readers may recognize the values of "II-M Intermittent Maximum" and "III-M Continuous Maximum" in Table I below as being part of the current regulations.

It was fortunate that by 1949 the IRT spray system was able to produce sprays similar to at least a portion of these values.

So, by 1951, NACA-RM-E51B12 could declare that the test conditions were "in the range of natural icing conditions".

References

- von Glahn, Uwe H., and Renner, Clark E.: Development of a Protected Air Scoop for the Reduction of Induction-System Icing. NACA-TN-1134, 1946. ntrs.nasa.gov

- Lewis, James P.: Wind-Tunnel Investigation of Icing of an Engine Cooling-Fan Installation. NACA-TN-1246, 1947. ntrs.nasa.gov

- Lewis, James P.: De-Icing Effectiveness of External Electric Heaters for Propeller Blades. NACA-TN-1520, 1948. ntrs.nasa.gov

- Lewis, James P., and Stevens, Howard C., Jr.: Icing and De-Icing of a Propeller with Internal Electric Blade Heaters. NACA-TN-1691, 1948. ntrs.nasa.gov

- Mulholland, Donald R., and Perkins, Porter J.: Investigation of Effectiveness of Air-Heating a Hollow Steel Propeller for Protection against Icing, I - Unpartitioned Blades. NACA-TN-1586, 1948. ntrs.nasa.gov

- Mulholland, Donald R., and Perkins, Porter J.: Investigation of Effectiveness of Air-Heating a Hollow Steel Propeller for Protection against Icing, III - 25-Percent Partitioned Blades. NACA-TN-1588, 1948. ntrs.nasa.gov

- Perkins, Porter J., and Mulholland, Donald R.: Investigation of Effectiveness of Air-Heating a Hollow Steel Propeller for Protection against Icing, II- 50-Percent Partitioned Blades. NACA-TN-1587, 1948. ntrs.nasa.gov

- von Glahn, Uwe H.: Ice Protection of Turbojet Engines by Inertia Separation of Water, I - Alternate-Duct System. NACA-RM-E8A27, 1948. ntrs.nasa.gov

- von Glahn, Uwe H.: Ice Protection of Turbojet Engines by Inertia Separation of Water, II - Single-Offset-Duct System. NACA-RM-E8A28, 1948. ntrs.nasa.gov

- von Glahn, Uwe H.: Ice Protection of Turbojet Engines by Inertia Separation of Water, III - Annular Submerged Inlets. NACA-RM-E8A29, 1948. ntrs.nasa.gov

- Dallas, Thomas, and Ellisman, Carl: Analysis and Preliminary Investigation of Eddy-Current Heating for Icing Protection of Axial-Flow-Compressor Blades. NACA-RM-E9EO6, 1949. ntrs.nasa.gov

- Ruggeri, Robert S., and Callaghan, Edmund E.: Experimental Investigation of Hot-Gas Bleedback for Ice Protection of Turbojet Engines, III - Nacelle with Short Straight Air Inlet. NACA-RM-E9E12, 1949. ntrs.nasa.gov

- Ruggeri, Robert S., von Glahn, Uwe H., and Rollin, Vern G.: Investigation of Aerodynamic and Icing Characteristics of Recessed Fuel-Vent Configurations. NACA-TN-1789, 1949. ntrs.nasa.gov

- Gray, Vernon H., and Bowden, Dean T.: Icing Characteristics and Anti-Icing Heat Requirements for Hollow and Internally Modified Gas-Heated Inlet Guide Vanes. NACA-RM-E50I08, 1950. ntrs.nasa.gov

- von Glahn, Uwe H., and Blatz, Robert E.: Investigation of Aerodynamic and Icing Characteristics of Water-Inertia-Separation Inlets for Turbojet Engines. NACA-RM-E50E03, 1950. ntrs.nasa.gov

- von Glahn, Uwe H., Callaghan, Edmund E., and Gray, Vernon H.: NACA Investigations of Icing-Protection Systems for Turbojet-Engine Installations. NACA-RM-E51B12, 1951. ntrs.nasa.gov

- Gelder, Thomas F., and Lewis, James P.: Comparison of Heat Transfer from Airfoil in Natural and Simulated Icing Conditions. NACA-TN-2480, 1951. ntrs.nasa.gov

- Gowan, W. H., Jr., and Mulholland, D. R.: Effectiveness of Thermal-Pneumatic Airfoil-Ice-Protection System. NACA-RM-E50K10a, 1951. ntrs.nasa.gov

- Perkins, Porter J., McCullough, Stuart, and Lewis, Ralph D.: A Simplified Instrument for Recording and Indicating Frequency and Intensity of Icing Conditions Encountered in Flight. NACA-RM-E51E16, 1951. ntrs.nasa.gov

- von Glahn, Uwe H., Callaghan, Edmund E., and Gray, Vernon H.: NACA Investigations of Icing-Protection Systems for Turbojet-Engine Installations. NACA-RM-E51B12, 1951. ntrs.nasa.gov

- Gray, Vernon H., Bowden, Dean T., and von Glahn, Uwe H.: Preliminary Results of Cyclical De-icing of a Gas-Heated Airfoil. NACA-RM-E51J29, 1952. ntrs.nasa.gov

- Lewis, James P., and Bowden, Dean T.: Preliminary Investigation of Cyclic De-Icing of an Airfoil Using an External Electric Heater. NACA-RM-E51J30, 1952. ntrs.nasa.gov

- Brun, Rinaldo J., Serafini, John S., and Moshos, George J.: Impingement of Water Droplets on an NACA 651-212 Airfoil at an Angle of Attack of 4°. NACA-RM-E52B12, 1952. ntrs.nasa.gov

- Gray, Vernon H., and Bowden, Dean T.: Comparison of Several Methods of Cyclic De-Icing of a Gas-Heated Airfoil. NACA-RM-E53C27, 1953. ntrs.nasa.gov

- Gray, Vernon H., and von Glahn, Uwe H.: Effect of Ice and Frost Formations on Drag of NACA 651-212 Airfoil for Various Modes of Thermal Ice Protection. NACA-TN-2962, 1953. ntrs.nasa.gov

- Lewis, James P.: Investigation of Aerodynamic and Icing Characteristics of Flush Alternate-Inlet Induction-Systems Air Scoop. NACA-RM-E53E07, 1953. ntrs.nasa.gov

- Lewis,James P., and Blade, Robert J.: "Experimental Investigation of Radome Icing and Icing Protection", NACA-RM-E52J31, 1953. ntrs.nasa.gov

- Ruggeri, Robert S.: De-Icing and Runback Characteristics of Three Cyclic Electric, External Deicing Boots Employing Chordwise Shedding. NACA-RM-E53C26, 1953. ntrs.nasa.gov

- von Glahn, Uwe H., and Gray, Vernon H.: Effect of Ice Formations on Section Drag of Swept NACA 63A-009 Airfoil with Partial-Span Leading-Edge Slat for Various Modes of Thermal Ice Protection. NACA-RM-E53J30, 1954. ntrs.nasa.gov

- Bowden, Dean T.: Investigation of Porous Gas-Heated Leading-Edge Section for Icing Protection of a Delta Wing. NACA-RM-E54I03, 1955. ntrs.nasa.gov

-

von Glahn, Uwe H., Gelder, Thomas F., and Smyers, William H., Jr.: A Dye-Tracer Technique for Experimentally Obtaining Impingement Characteristics of Arbitrary Bodies and a Method for Determining Droplet Size Distribution. NACA-TN-3338, 1955. ntrs.nasa.gov

-

Coles, Willard D.: Icing Limit and Wet-Surface Temperature Variation for Two Airfoil Shapes under Simulated High-Speed Flight Conditions. NACA-TN-3396, 1955. ntrs.nasa.gov

- Bowden, Dean T.: Effect of Pneumatic De-Icers and Ice Formations on Aerodynamic Characteristics of an Airfoil. NACA-TN-3564, 1956. ntrs.nasa.gov

- Gelder, Thomas F., Smyers, William H., Jr., and von Glahn, Uwe H.: Experimental Droplet Impingement on Several Two-Dimensional Airfoils with Thickness Ratios of 6 to 16 Percent. NACA-TN-3839, 1956. ntrs.nasa.gov

- Gray, Vernon H., and von Glahn, Uwe H.: Heat Requirements for Ice Protection of a Cyclically Gas-Heated, 36 Swept Airfoil with Partial-Span Leading-Edge Slat. NACA-RM-E56B23, 1956. ntrs.nasa.gov

- von Glahn, Uwe H.: Use of Truncated Flapped Airfoils for Impingement and Icing Tests of Full-Scale Leading-Edge Sections. NACA-RM-E56E11, 1956. ntrs.nasa.gov

- Gray, Vernon H., and von Glahn, Uwe H.: Aerodynamic Effects Caused by Icing of an Unswept NACA 65A004 Airfoil. NACA-TN-4155, 1958. ntrs.nasa.gov

- Gelder, Thomas F.: Total Pressure Distortion and Recovery of Supersonic Nose Inlet with Conical Centerbody in Subsonic Icing Conditions. NACA-RM-E57G09, 1957. ntrs.nasa.gov

- Gelder, Thomas F.: Droplet Impingement and Ingestion by Supersonic Nose Inlet in Subsonic Tunnel Conditions. NACA-TN-4268, 1958. ntrs.nasa.gov

Related

Today, SAE ARP5905, Calibration and Acceptance of Icing Wind Tunnels (Aerospace Recommended Practice) 2 "provides recommended practices for the calibration and acceptance of icing wind tunnels to be used in testing of aircraft components and systems and for the development of simulated ice shapes".

You can see a recent calibration of the NASA Glenn Icing Research Tunnel at ntrs 7.

Notes

I thank Emily Timko (lead author of 7) for reviewing a draft of this post. I edited the post after it was reviewed, and any errors are mine.

-

NACA Annual Report for 1929 discussing the Langley Refrigerated Wind Tunnel, via NASA-SP-2002-4226, "We Freeze to Please": A History of NASA's Icing Research Tunnel and the Quest for Flight Safety ↩

-

Aerospace, S. A. E. "SAE ARP 5905 Calibration and acceptance of icing wind tunnels." ARP5905 ↩↩

-

Knight, Montgomery, and Clay, William C.: Refrigerated Wind Tunnel Tests on Surface Coatings for Preventing Ice Formation. NACA-TN-339, 1930 ntrs.nasa.gov. ↩

-

Rodert, Lewis A.: A Preliminary Study of the Prevention of Ice on Aircraft by use of Engine Exhaust Heat. NACA-TN-712, 1939. ntrs.nasa.gov ↩

-

NACA Conference on Aircraft Ice Prevention A Compilation of Papers Presented by NACA Staff Members. 6505/NACA-1947/8, 1947.

This is available at DTIC.

This is also a candidate for "The Greatest Thing That You Have (Probably) Never Read" ↩ -

Jones, Alun R., and Lewis, William: Recommended Values of Meteorological Factors to be Considered in the Design of Aircraft Ice-Prevention Equipment. NACA-TN-1855, 1949. ntrs.nasa.gov ↩

-

Timko, Emily N., et al. NASA Glenn Icing Research Tunnel: 2019 Cloud Calibration Procedure and Results. No. E-19889. 2021. ntrs.nasa.gov ↩↩