"A measure of the concentration of liquid water in a supercooled cloud is of considerable value in determining the severity of aircraft icing conditions"

"A Simplified Instrument for Recording and Indicating Frequency and Intensity of Icing Conditions Encountered in Flight"

Summary

An instrument for automatically recording the occurrence of icing and liquid water content values is described.

Key Points

- The instrument relied on the plugging of holes exposed to icing, which made a measurable pressure difference.

- The instrument was cyclically deiced with electric heating.

- Data was recorded on film that was later processed.

- The instrument was used on numerous flights.

Abstract

An instrument for recording and indicating the frequency and intensity of aircraft icing conditions has been developed by the NACA Lewis laboratory to obtain statistical icing data over world-wide air routes during routine airline operations. An accumulation of data of this type is needed to provide pertinent meteorological information necessary for the optimum design of ice-protection systems. The operation of the instrument is based on the creation of a differential pressure between an ice-free total-pressure system and a total-pressure system in which small total-pressure holes vented to static pressure are allowed to plug with ice accretion. At a fixed value of ice accretion, the differential pressure operates an electrical heater that de-ices the total-pressure holes. The resulting cyclic process varies with the intensity of the icing and serves as a measure of the icing rate. The simplicity of this operating principle permits automatic operation upon encountering an icing condition, and relative freedom from maintenance and operating problems. The complete unit weighs only 18 pounds. Icing rate, airspeed, and altitude hours of continuous are recorded on photographic film providing data. Visual indications of the icing intensity are made available to the pilot by periodic flashing of a light on the instrument panel.

The indications of icing rate from the instrument were calibrated against the rotating-disk type of icing-rate meter. Recorded values of icing rate and airspeed provide a means of obtaining values of cloud liquid-water content based on the multicylinder method for measuring supercooled cloud quantities.

Discussion

The publication is succinct,

and the online version has good quality scanned images.

I will let it tell its story with selected extracts.

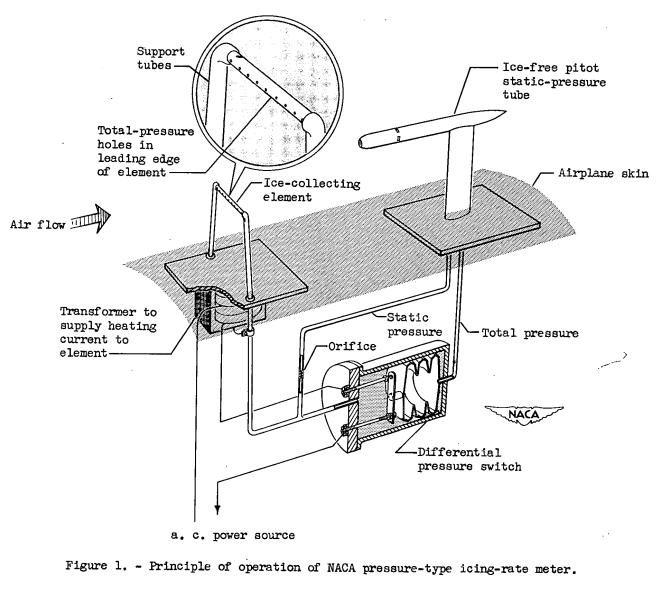

OPERATING PRINCIPLE The instrument operates on differential pressure created when small total-pressure holes plug with ice accretions, as illustrated in the sketch of figure 1. The small total-pressure holes in the ice-collecting element, which are vented to static pressure through a small orifice, are balanced against a nonvented, ice-free total pressure in a differential pressure switch. When these small total-pressure holes plug from ice accretion, the pressure in the corresponding side of the pressure switch approaches static by bleeding through the static orifice and a differential pressure is created between the iced and ice-free systems. Continuous operation is obtained by allowing the differential-pressure switch to energize an electric heater that de-ices the ice-plugged total-pressure holes. The pressures in the two systems then tend to equalize, opening the pressure switch and allowing the cycle to be repeated. The heat-off time of this cyclic process is used as a measure of the period of time required to plug the holes. This period is a function of the rate at which ice accumulates on the element containing the holes because the amount of ice accretion required for plugging is a constant value. The duration of the heat-off period is calibrated against a measured icing rate in order to obtain a measure of icing rate from the heat-off period. The rate of icing thus measured is a function of cloud liquid-water content and air velocity. In order to obtain cloud liquid-water content, the air velocity is measured simultaneously with the heat-off or icing period.

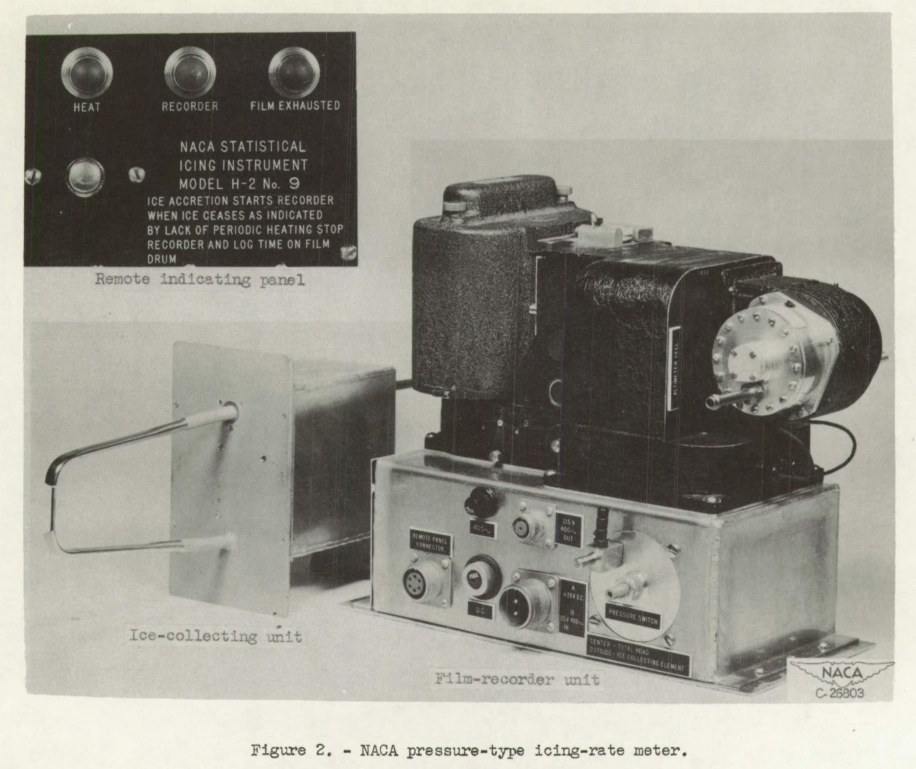

An NACA flight-type film recorder is used to record continuously the duration of the heat-off or icing period, the heat-on or de-icing period, the indicated airspeed, and the altitude. The recorder is semiautomatic in that the initial plugging starts the recorder, which operates continuously until turned off manually after an icing encounter. The recorder may be supplemented with a remote panel equipped with indicating lights that can be installed in the pilots' compartment for visual indications of the icing intensity and the operation of the recorder during flight. An icing encounter is indicated by periodic flashing of a light parallel with the heating circuit; thus, the time between flashes can be used as an indication of the icing intensity. Another light on this panel indicates the operation of the recorder, and a third light indicates when the recording film is exhausted.

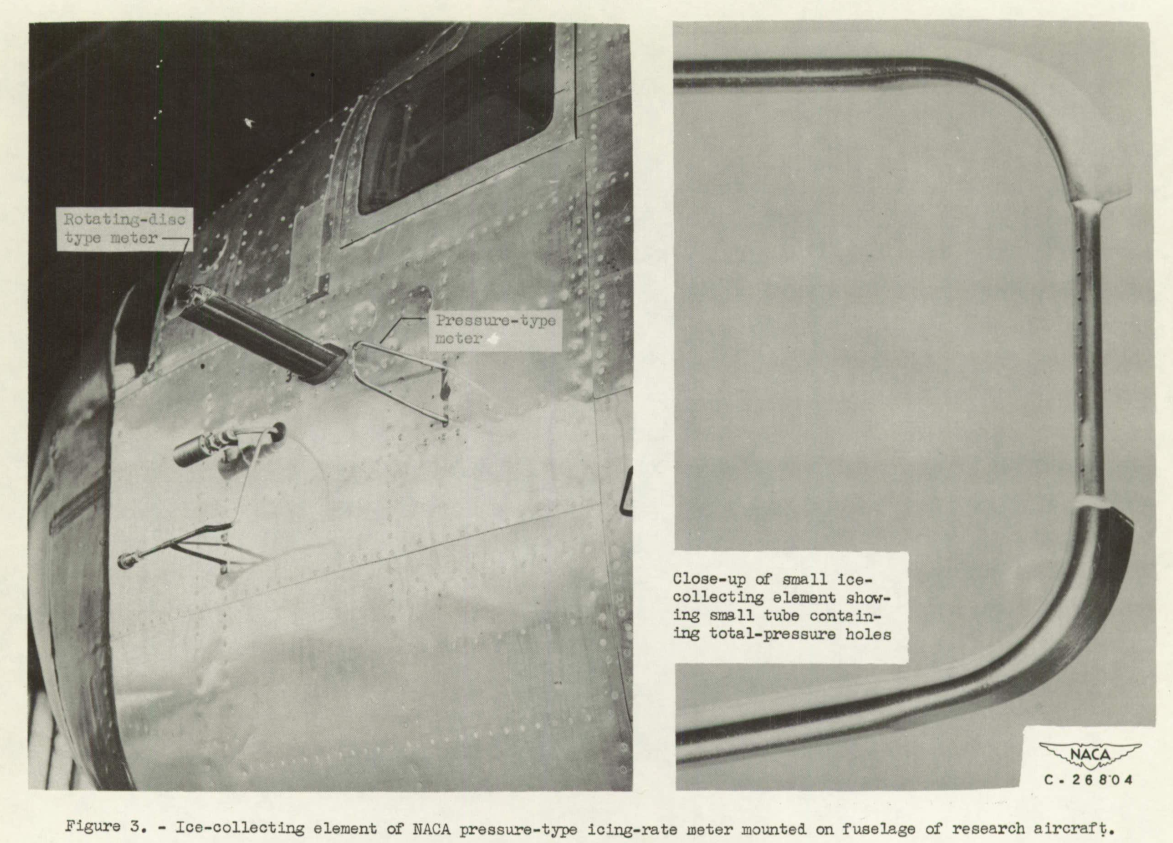

The ice-collecting unit (close-up in fig. 3) is a "U"-shape tubular construction with 10 small total-pressure holes (0.014-in. diain.) drilled in the side of a small phosphor-bronze tube(0.100-in. diam.) attached at the bottom of the "U". The multiple number of holes is considered necessary to prevent erratic plugging from large droplets or foreign material. The larger tubes of nickel alloy at the sides of the "U" support this small tube about 6 inches from a brass plate that fastens to the skin of the aircraft. Figure 3 shows this unit mounted on the left side of the fuselage ahead of the propeller plane of a twin-engine research aircraft. The "U"-shape unit is mounted normal to the air stream with the total-pressure holes in the small tube on the upstream side.

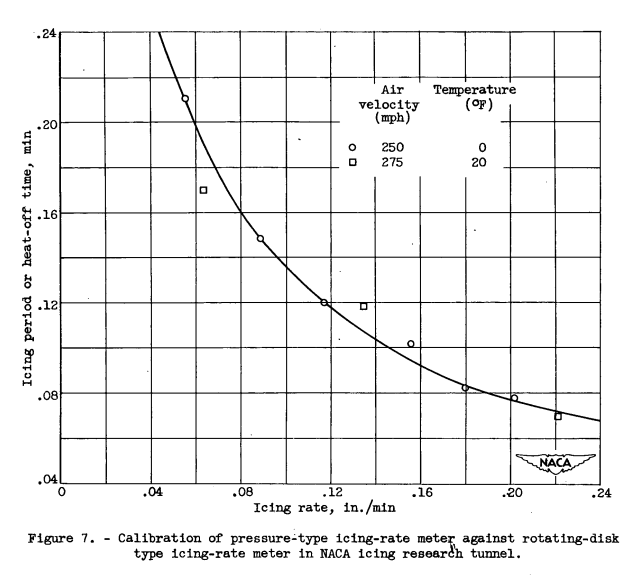

The pressure-type meter was calibrated in the tunnel for rate of Icing by varying the liquid-water content and the velocity of the air stream. Both meters were mounted so that the ice-collecting elements were within 2 Inches of each other to assure the same icing conditions for both instruments. The results of this calibration (fig. 7) show that the icing period or heat-off time varies between 0.21 to 0.07 minute (13 to 4 sec) for an icing-rate range of 0.055 to 0.22 inch per minute (3 to 13 in./hr). The variation of slope of the calibration curve provides the greatest reading accuracy at the low icing rates, but the accuracy decreases as the icing rate becomes greater to a point where the icing period becomes almost insensitive to large changes of icing rate. The maximum limit of operation occurs at the point where the heat must stay on continuously to keep the total-pressure holes ice-free. The reading error varies from ±2 percent at the low icing rate to ±20 percent at the measurable high icing rates. The reading accuracy of the disk-type meter varies between 12 percent at the low icing rate to ±6 percent at the high icing rate, thus providing a total maximum error in the calibration of about ±14 percent at the low icing rates to ±26 percent at the high icing rates. No effects of air temperature on the icing-rate calibration were noted between 0° and 20° F.

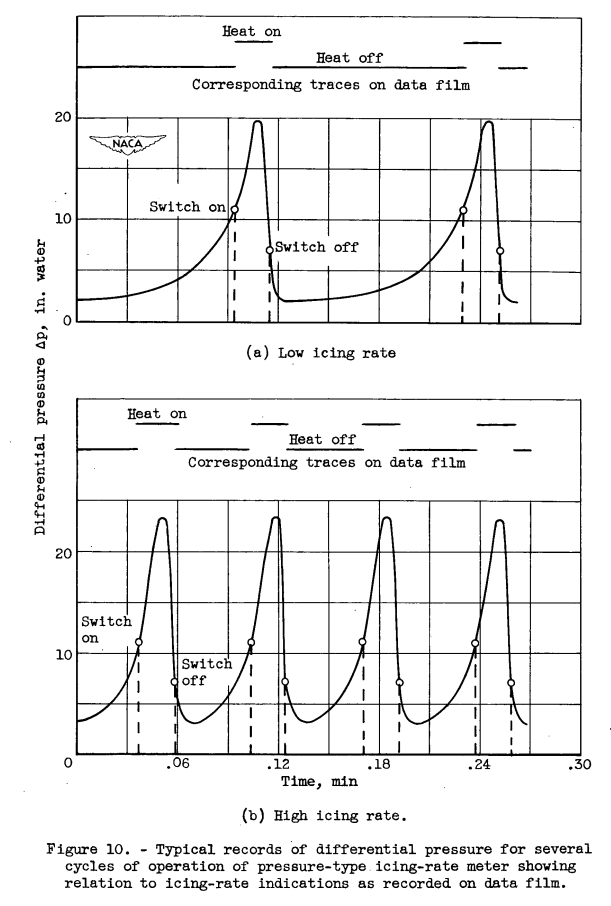

The differential-pressure records shown in figure 10 were taken at both a high and low icing rate to show the variation in the differential-pressure changes at each condition and the resulting traces that are recorded on the standard data film. The length of the heat-off line can be used as a direct measure of the icing rate provided the speed of the film travel is known. The heat-on or de-icing period does not change appreciably with icing rate but is affected more by air temperature and velocity.

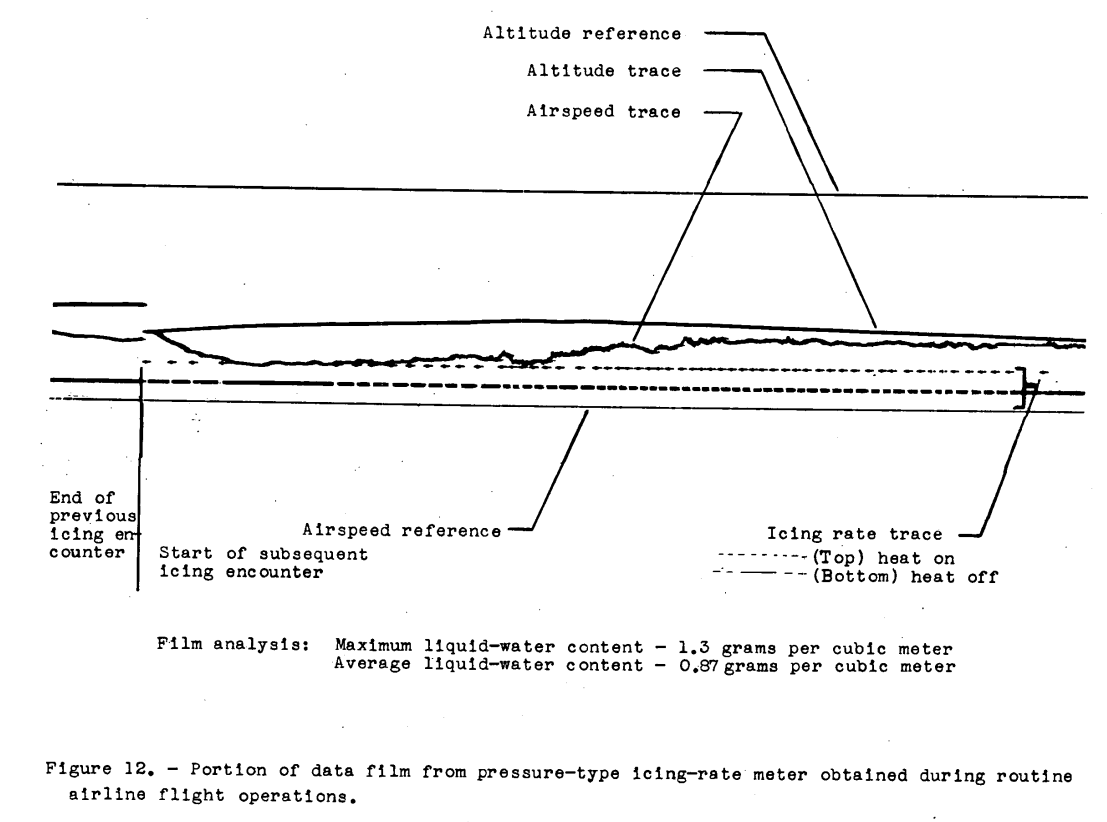

TYPICAL DATA After the development and calibration of the instrument, arrangements were made to install several of these units on commercial airliners. Part of a typical data film obtained from an icing condition encountered during a routine airline flight is shown in figure 12. Airspeed, altitude, icing rate, and duration of the icing condition can be obtained from this record. With notations by the pilot of time, data, temperature, and geographic location, this record gives sufficient information for a complete meteorological analysis of the particular icing encounter. Values of liquid-water content can be obtained from the icing rate said airspeed records using the calibration previously, described. Each film roll usually contains several encounters in sequence, which must be correlated with the pilot's log.

Conclusions

An instrument for recording and indicating the frequency and intensity of aircraft icing conditions has been developed by the NACA Lewis laboratory for obtaining statistical icing data over world-wide air routes from routine airline operations. The instrument operates on differential pressure created when small total-pressure holes in a static-pressure vented system, which is balanced against an ice-free total-pressure system, are allowed to plug with ice accretions.

The features that make the instrument desirable for use during routine airline operations are: (1) simplicity of operation, (2) freedom from maintenance and operating problems, (3) automatic operation upon encountering an icing condition, (4) visual indications of icing intensity available to the pilot, (5) total weight of 18 pounds, and (6) continuous recorded data. Recorded values of icing rate and airspeed provide a means of calculating cloud liquid-water content based on the multicylinder method for measuring supercooled cloud quantities.

The instrument was later used, and described in NASA TM 83564 4, as the "Pressure-type Icing Rate and Accretion Meter (PIRAM)".

The instrument was used to survey icing conditions along commercial airline routes 2, 3. Data from hundreds of flights where measured. However, this seemingly valuable data saw surprisingly limited use, something that we will soon look at in the "Conclusions of the Meteorological Instruments Thread".

Citations

NACA-RM-E51E16 cites three publications.

- Vonnegut, B., Cunningham, R. M., and Katz, R. E.: Instruments for Measuring Atmospheric Factors Related to Ice Formation on Airplanes. De-Icing Res. Lab., Dept. Meteorology, M.I.T., April 1946.

- Clark, Victor F.: The Multicylinder Method. Mt. Wash. Observatory Monthly Res. Bull., vol. II, no. 6, June 1946.

- Langmuir, Irving, and Blodgett, Katherine B.: A Mathematical Investigation of Water Droplet Trajectories. Tech. Rep. No. 5418, Air Materiel Command, AAF, Feb. 19, 1946. (Contract No. W-33-038-ac-9151 with General Electric Co.)

NACA-RM-E51E16 is cited by 10 publications in the NACA Icing Publications Database 5:

- Brun, Rinaldo J., Serafini, John S., and Moshos, George J.: Impingement of Water Droplets on an NACA 651-212 Airfoil at an Angle of Attack of 4°. NACA-RM-E52B12, 1952. ntrs.nasa.gov

- Perkins, Porter J.: Preliminary Survey of Icing Conditions Measured During Routine Transcontinental Airline Operation. NACA-RM-E52J06, 1952. ntrs.nasa.gov

- Gray, Vernon H., and von Glahn, Uwe H.: Effect of Ice and Frost Formations on Drag of NACA 651-212 Airfoil for Various Modes of Thermal Ice Protection. NACA-TN-2962, 1953. ntrs.nasa.gov

- Dorsch, Robert G., and Brun, Rinaldo J.: Variation of Local Liquid-Water Concentration about an Ellipsoid of Fineness Ratio 5 Moving in a Droplet Field. NACA-TN-3153, 1954. ntrs.nasa.gov

- Neel, Carr B., Jr.: A Heated-Wire Liquid-Water-Content Instrument and Results of Initial Flight Tests in Icing Conditions. NACA-RM-A54I23, 1955. ntrs.nasa.gov

- Perkins, Porter J.: Statistical Survey of Icing Data Measured on Scheduled Airline Flights over the United States and Canada from November 1951 to June 1952. NACA-RM-E55F28a, 1955. ntrs.nasa.gov

- Bowden, Dean T.: Effect of Pneumatic De-Icers and Ice Formations on Aerodynamic Characteristics of an Airfoil. NACA-TN-3564, 1956. ntrs.nasa.gov

- Hacker, Paul T.: An Oil-Stream Photomicrographic Aeroscope for Obtaining Cloud Liquid-Water Content and Droplet Size Distribution in Flight. NACA-TN-3592, 1956. ntrs.nasa.gov

- Gray, Vernon H., and von Glahn, Uwe H.: Aerodynamic Effects Caused by Icing of an Unswept NACA 65A004 Airfoil. NACA-TN-4155, 1958. ntrs.nasa.gov

- Perkins, Porter J.: Icing Frequencies Experienced During Climb and Descent by Fighter-Interceptor Aircraft. NACA-TN-4314, 1958. ntrs.nasa.gov

An online search found NACA-RM-E51E16 cited by 18 publications 6.

Notes

-

Perkins, Porter J., McCullough, Stuart, and Lewis, Ralph D.: A Simplified Instrument for Recording and Indicating Frequency and Intensity of Icing Conditions Encountered in Flight. NACA-RM-E51E16, 1951. ntrs.nasa.gov ↩

-

Perkins, Porter J.: Preliminary Survey of Icing Conditions Measured During Routine Transcontinental Airline Operation. NACA-RM-E52J06, 1952. ntrs.nasa.gov ↩

-

Perkins, Porter J.: Statistical Survey of Icing Data Measured on Scheduled Airline Flights over the United States and Canada from November 1951 to June 1952. NACA-RM-E55F28a, 1955. ntrs.nasa.gov ↩

-

Ranaudo, R., J.; Mikkelsen, K. L.; McKnight, R. C. and Perkins, P. J. Jr., "Performance Degradation of a Typical Twin Engine Commuter Type Aircraft in Measured Natural Icing Conditions," NASA TM 83564 and AIAA-84-0179, 1984. ntrs.nasa.gov ↩